Making plant-based meat alternatives more palatable

One of the biggest obstacles to the uptake of plant-based alternatives to meat is their very dry and astringent feel when they are eaten.

Scientists, led by Professor Anwesha Sarkar and supported by the atomic force microscope (AFM) facility within the School of Physics and Astronomy, are revolutionising the sensation of plant proteins by transforming them from a substance often experienced as gloopy and dry into one that is juicy and fat like.

What’s more, the only substance being added to these plant proteins is water.

Plant protein microgels

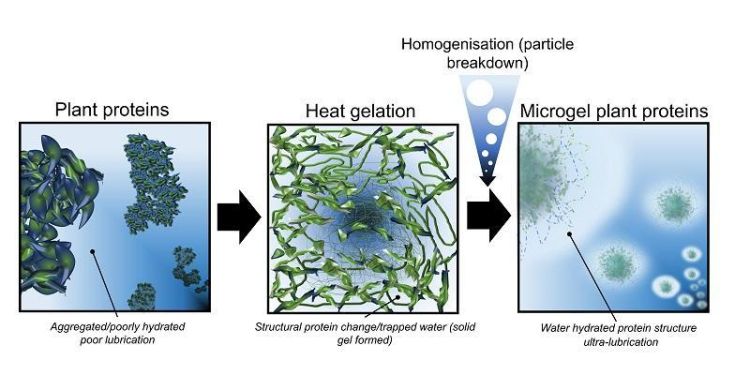

To bring about this change, the scientists created plant protein microgels through a process called microgelation.

Plant proteins – which start off dry, with a rough texture – are placed in water and heated. This alters the structure of the protein molecules, which come together to form an interconnected network or gel that traps water around the plant proteins.

The gel is then homogenised, which breaks the protein network into a microgel made up of tiny particles that cannot be seen with the naked eye. Under pressure, as they would be when they are being eaten, the microgels ooze water, creating a lubricity akin to that of single cream.

Professor Sarkar said: “What we have done is converted the dry plant protein into a hydrated one, using the plant protein to form a spider-like web that holds the water around the plant protein.

“This gives the much-needed hydration and juicy feel in the mouth.

“Plant-based protein microgels can be created without having to use any added chemicals or agents using a technique that is widely available and currently used in the food industry. The key ingredient is water.”

The graphic shows how the plant protein microgels are made. Water is added and the plant proteins, which are then heated. They form a gel which is broken down into a microgel. The plant protein microgel has a lubricity similar to that of a single cream. Credit: Ben Kew, University of Leeds.

Revitalising consumer interest

The research team, who published their findings in the scientific journal Nature Communications, say the dryness of plant proteins has been a “key bottle neck for consumer acceptability”.

With the breakthrough, researchers hope that consumer interest in plant-based proteins will be revitalised, encouraging people to reduce their reliance on animal products for protein intake – a necessary step if global climate change targets are to be met.

More than half of the 18 billion tonnes of carbon dioxide equivalents produced each year from food production comes from rearing and processing animal products.

The researchers say the protein microgels “offer a unique platform to design the next generation of healthy, palatable and sustainable foods”.

Eureka moment

Throughout the investigation, the team had mathematically modelled the behaviour of plant protein microgels and were confident their approach would work.

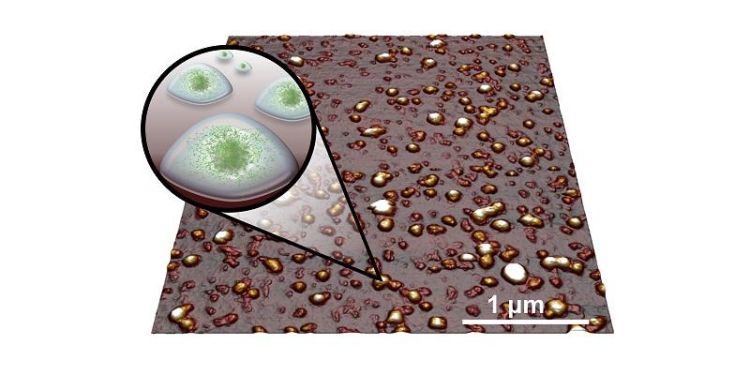

But the proof came in visualisations produced in the atomic force microscopy suite in the Faculty of Engineering and Physical Sciences at Leeds.

Dr Lekshmi Kailas, an Experimental Officer in AFM at the School of Physics and Astronomy who helps train PhD students to use the equipment – including those working with Professor Sarkar – explained that the technology uses a tiny but sharp probe to scan across surfaces, producing topographical images and mechanical maps with resolution down to the nanoscale.

What those images revealed amounted to a proof of concept.

Dr Simon Connell, Associate Professor at the School of Physics and Astronomy, said: “I look after the AFM facility, and I was directly involved in this project. I actually did the AFM imaging myself – it’s a bit rare for an academic of my vintage to still work in the lab!

“You can think of these protein microgels as tiny blobs of jelly. As they are about 100nm in size, this is smaller than an optical microscope can see. They are also largely made up of water, and if you put them in the high-vacuum environment of an electron microscope, they dry out quickly and you are left with a flat dry pancake on the surface.

“Because AFM is a mechanical probe technique, it can operate underwater, so can image the gel when it’s fully hydrated and soft, therefore getting a better measurement of its size, shape and texture in its natural state.”

Professor Sarkar added: “Seeing the images from the atomic force microscope was an exciting moment for us. The visualisations revealed that the protein microgels were pretty much spherical and not aggregating or clumping together. We could see individually spaced plant protein microgels.

“Our theoretical studies had said this is what would happen but there is nothing quite like seeing it for real.”

Dr Mel Holmes, Associate Professor in the School of Food Science and Nutrition at Leeds and one of the authors of the paper, said: “This study reveals the ingenuity and depth of science involved in modern food technology, from the chemistry of proteins, the way food is sensed in the mouth to an understanding of tribology - the friction between materials and sensory cells in the mouth.

“Tackling the big questions in food science requires interdisciplinary science.”

Wider spin offs of plant protein microgels

Given the lubricity of the microgels, akin to that of a single cream, means they could be adapted for other uses in the food processing industry, such as replacing fat that has been removed from a foodstuff to develop healthier options.

Ben Kew, doctoral researcher in the School of Food Science and Nutrition at Leeds and lead scientist in the project, said: “This is quite a remarkable finding. It is striking that without adding a drop of fat, the microgels have the lubricity of a 20% fat emulsion, which we are the first to report.

“Our experimental data supported by theoretical analyses also mean we could begin to use these plant protein microgels in foods where fat has to be removed to reformulate into healthier next generation plant protein food options.”

Further information

- The paper, Transforming sustainable plant proteins into high performance lubricating microgels, can be downloaded from the Nature Communications website. The authors are: Ben Kew, Melvin Holmes, Evangelos Liamas, Rammile Ettelaie, Simon Connell, Daniele Dini, and Anwesha Sarkar.

- For more information on the research, email University of Leeds press officer David Lewis at d.lewis@leeds.ac.uk