Particle and materials characterisation

- Overview: Analytical facilities for characterisation of particles, powders, slurries, suspensions, emulsions and solutions.

- Contact name: Dr Ben Douglas

- Phone: +44 (0)113 343 2378

- Email: b.douglas@leeds.ac.uk

We have a range of instruments for obtaining particle size distributions from a few nanometres up to hundreds of micrometres in size, for particulate-based systems in wet or dry dispersions.

Particle morphology can be studied using a specialised light microscope with image analysis, or a bench-top electron microscope with elemental mapping.

Other solid materials characterisation includes surface area and porosity instruments and vapour sorption equipment.

Rheometers are available to study viscosity and flow properties of liquids and semi-solids.

Equipment

- Dynamic Light Scattering: The Malvern Zetasizer calculates particle size distributions from light intensity measurements of nanoparticles (a few nanometres up to 10 microns depending on system properties) dispersed in a liquid.

- Laser diffraction: A Malvern Mastersizer 2000E can be used to measure particle size distributions in the range 0.1 – 1000 microns. Materials can be dispersed in a liquid or studied as dry powders.

- Particle tracking: An alternative method of obtaining a particle size distribution consists of tracking the movement of the particles under a microscope using the Nanosight LM10. The interference fringes detected from light scattered by the suspended material are used to calculate the size of the particles.

- Centrifugation: Particle size can also be measured using the CPS Disc Centrifuge DC24000, which measures particle settling rates through a known density gradient under high speed rotation. This information can then be used to calculate a particle size distribution.

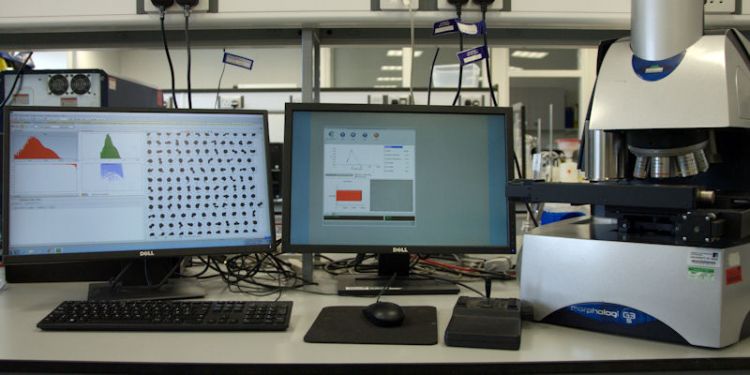

- Particle size and shape: The Malvern Morphologi G3 is a microscope based imaging instrument which analyses tens of thousands of individual particles to produce information on particle size and morphology. A dynamic system, the FlowCAM, captures similar data using a flow cell and a strobed light source.

- Bench-top Scanning Electron Microscopy with Energy Dispersive X-ray analysis: Two Hitachi TM3030Plus scanning electron microscopes (SEMs) are used for a wide variety of samples for quick and accessible imaging. One microscope is equipped with an automated xy stage, the other with an Oxford X-ray analysis system for elemental identification and mapping (EDX).

- Sedimentation and stability analysis: Settling or creaming behaviour can be studied under gravity using a Fullbrook Turbiscan instrument, or under centrifugal conditions with the LUM LumiSizer, by measuring changes in light transmittance through the sample at time intervals. This can also give information on particle size (20 nanometres – 100 microns).

- Zetapotential: Malvern Zetasizer and Colloidal Dynamics Zetaprobe instruments are available to measure surface charge of suspended particles (zeta potential) via electrophoretic or electroacoustic techniques.

- Surface area and porosity: Nitrogen adsorption can be used to measure surface areas (e.g. BET analysis) and pore sizes or volumes of micro and mesoporous solids using Micromeritics Tristar 3000 or Quantachrome Nova 2200e instruments.

- Dynamic vapour sorption: The Surface Measurement Systems DVS Resolution monitors sample mass under controlled temperature and relatively humidity. Water or organic solvent uptake can be measured.

- Density measurement: A helium pycnometer is available to measure density of solids, and tapped densities can also be measured using a Copley instrument.

- Rheology: Malvern Bolin Gemini and Anton Paar Physica MCR301 rotational rheometers are used to measure viscosity, creep, relaxation or oscillation at variable temperatures and shear rates. Cone and plate, cup and bob, and vane geometries are available.

- Surface tension and contact angle: Drop shape analysis using the KSV tensiometer can be used to measure contact angles of liquid droplets on surfaces and surface/interfacial tensions of liquids.

Applications

Solid catalysts, pharmaceuticals, emulsions, polymers, nanoparticles, fuels and personal care.

Who can use the facility?

We are committed to sharing our facilities and associated expertise with external academic and industrial collaborators.

Location

School of Chemical and Process Engineering, laboratory 2.01