Flow-Xl: A New UK Facility for Analysis of Crystallisation in Flow Systems

- Overview: Flow-Xl enables the in-situ, time-resolved characterisation of crystallisation processes in highly controlled environments using combined X-ray diffraction and Raman Spectroscopy.

- Contact name: Prof. Fiona Meldrum

- Phone: +44(0)113 343 6414

- Email: F.Meldrum@leeds.ac.uk

Flow-Xl enables in-situ, time-resolved characterisation of crystallisation processes in highly controlled environments. This is achieved by coupling state of the art laboratory X-ray diffraction and Raman spectroscopy to a range of fully-integrated flow platforms. These analytical techniques can be used simultaneously to study crystallisation pathways from amorphous and poorly crystalline precursor materials, through crystalline intermediates, to the ultimate crystal products.

This combined capability is not currently available anywhere else in the world. Flow-Xl is also extremely timely, where it is only possible because top-of-the-range laboratory X-ray instruments are now so good that they can replace synchrotrons for many experiments. Flow-Xl will also enable us to share our expertise in the manufacture of flow-cells for X-ray measurements with the entire UK research community.

Equipment

- Rigaku XtaLab Synergy Custom X-Ray Diffractometer

- XYZ Motorised Sample Translation Stage

- Horiba Labram HR Evolution Raman Microscope w/ External Raman Probe

- 0.5L Jacketed Process Crystallisation Vessel

- 4x Cetoni Syringe Drivers

- Linkam RH96 Humidity Generator

- In-Situ Flow Cells for Liquid/Slurry Samples

- Variable Humidity Cell for Powders

- F-Reactor Continuous Crystallisation Equipment

- Micro/Milli-fluidic Devices for Segregated Crystallisation

- Acoustic Droplet Levitator

The facility has a state of the art Rigaku XtaLAB Synergy Custom X-ray diffractometer, with a Cu micro-focus rotating anode X-ray source for ultra-high brightness at the sample, optimised towards data collection from the weakest of diffracting samples. The system is also configured with a Hybrid Photon Counting (HPC) X-ray detector, the HyPix-6000HE, with high dynamic range, fast readout speed and extremely low noise, the system is set-up to collect low noise data quickly, ideal for in-situ diffraction studies of samples in flow. The new Synergy Custom diffractometer will allow users to easily mount a variety of in-situ flow cells and microfluidic devices onto the robust XtalCheckS accessory which sits on a four circle goniometer for complete data collection.

Additionally the set-up has a Raman spectrometer, a Labram HR Evolution from HORIBA Jobin Yvon, with both green (532 nm) and red (785 nm) lasers with respective ultra-low frequency (ULF) modules allowing measurements in the sub-100 cm-1 region, with measurements down to 10 cm-1 routinely available. Two SuperHead fiber optic probes will facilitate in-situ measurements at samples contained within the new X-ray diffractometer enclosure.

The facility has a large range of sample environments and peripheral equipment to allow users to design and carry out crystallisation experiments. These include a 0.5L temperature controlled jacketed batch crystallisation vessel, syringe drivers for micro/milli-fluidic continuous crystallisation experiments, temperature programmable chillers, peristaltic pumps and stirrers. There is also a humidity controller and chamber for carrying out variable humidity/temperature experiments on powder samples. The facility contains a number of sample cells for users; a slurry flow cell, microfluidic devices, continuous crystallisation reactors, acoustic levitator, humidity chamber and powder holders.

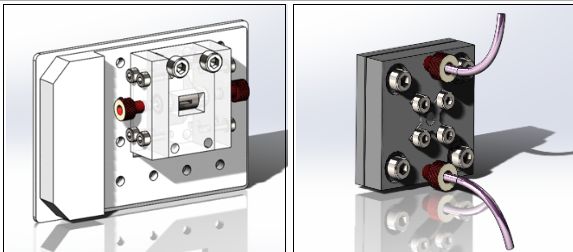

In-situ capillary flow cell for liquids (left) and variable humidity cell for powders (right)

Applications

- Characterisation of Solution Mediated Phase Transformations

- Identification of Structural Pathways During Crystallisation

- Quantitative Analysis of Phase Transformations and Growth Kinetics

Partners and sponsors

- Centre for Continuous Manufacturing and Crystallisation (CMAC)

- University of Nottingham

- UKRI - EPSRC

Who can use the facility?

Flow-Xl will be operated as a multi-user facility that is open to all academic and industrial researchers across the UK, and will be supported by an experienced research officer. This will allow the equipment to be fully utilised for a wide range of projects spanning industrial processes through to developing fundamental understanding.

In addition to providing a cutting-edge, stand-alone research facility, Flow-Xl will also support Diamond Light Source and its users by providing an alternative or precursor to synchrotron time for many experiments. This frees-up precious beam-time for experiments that really need it, and enables researchers to conduct screening/ feasibility experiments prior to their beam-time.

Location

G52B School of Chemistry, University of Leeds

Members of staff

Contact

- Prof. Fiona Meldrum; F.Meldrum@leeds.ac.uk +44(0)113 343 6414

- Prof. Nikil Kapur N.Kapur@leeds.ac.uk +44(0)113 343 2152

- Prof. Alistair Florence: alastair.florence@strath.ac.uk

- Dr Karen Robertson Karen.Robertson@nottingham.ac.uk 01159514111

- Dr Thomas Turner T.D.Turner@leeds.ac.uk +44 (0) 113 343 7337